Machining

Portfolio

This page contains a few of the parts I have machined. The manufacturing of these parts took place both within my co-op placement at the UVic Mechanical Engineering Machine Shop as well as afterwards when making parts for various university engineering clubs

Featured Projects

Innovative engineering solutions addressing critical environmental challenges through cutting-edge technology and sustainable design.

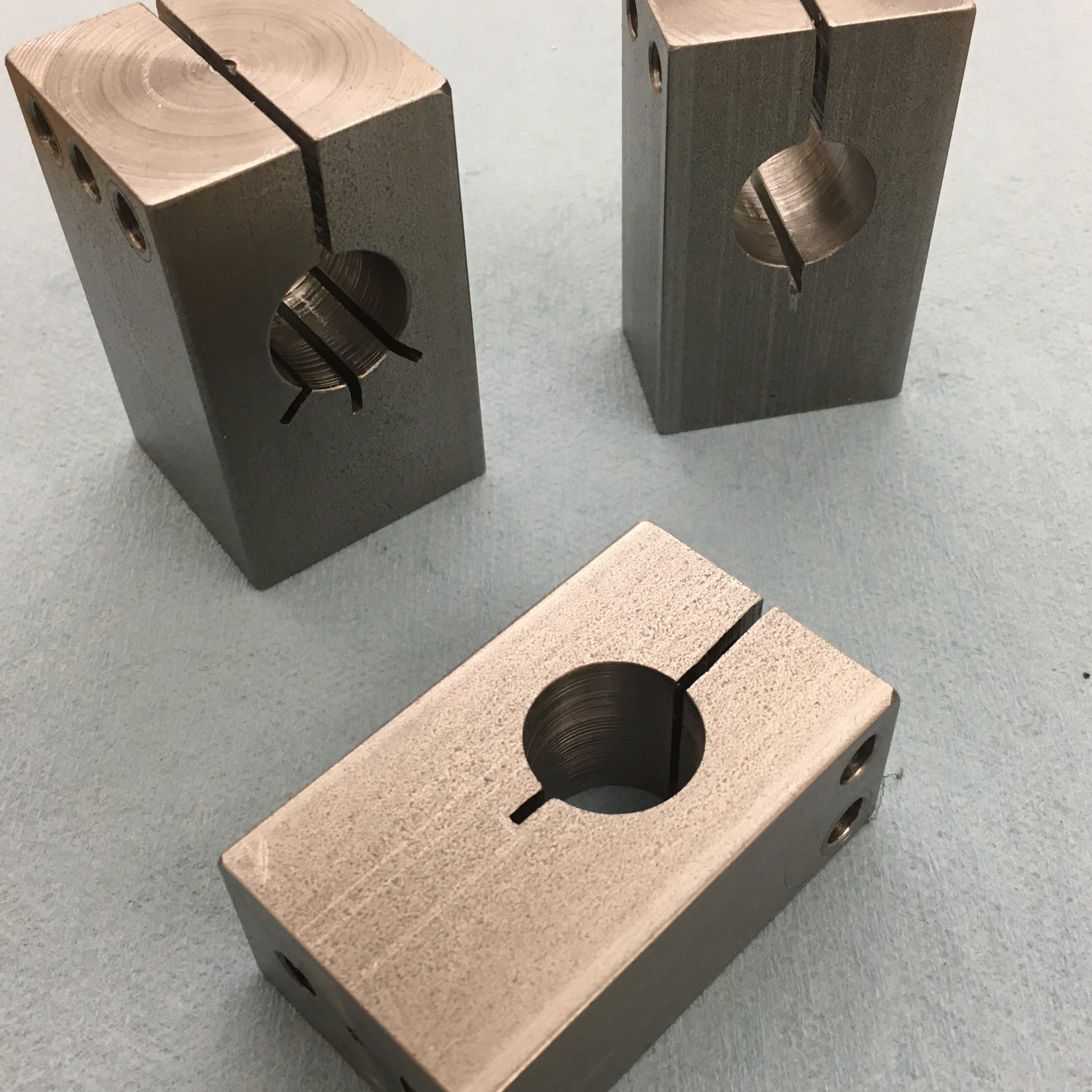

Mild Steel Parts

This project involved milling and turning operations on mild steel. These parts were used for helmet impact testing.

Laser Cut Parts

During my co-op, the MECH Machine Shop laser was frequently used for cutting parts for student projects. I also cut several flywheel powered carts from plywood for a 3rd year design project, as shown in the photos.

Tuning Forks

Aluminum, brass, and Delrin tuning forks were cut on the waterjet for a material science lab experiment.

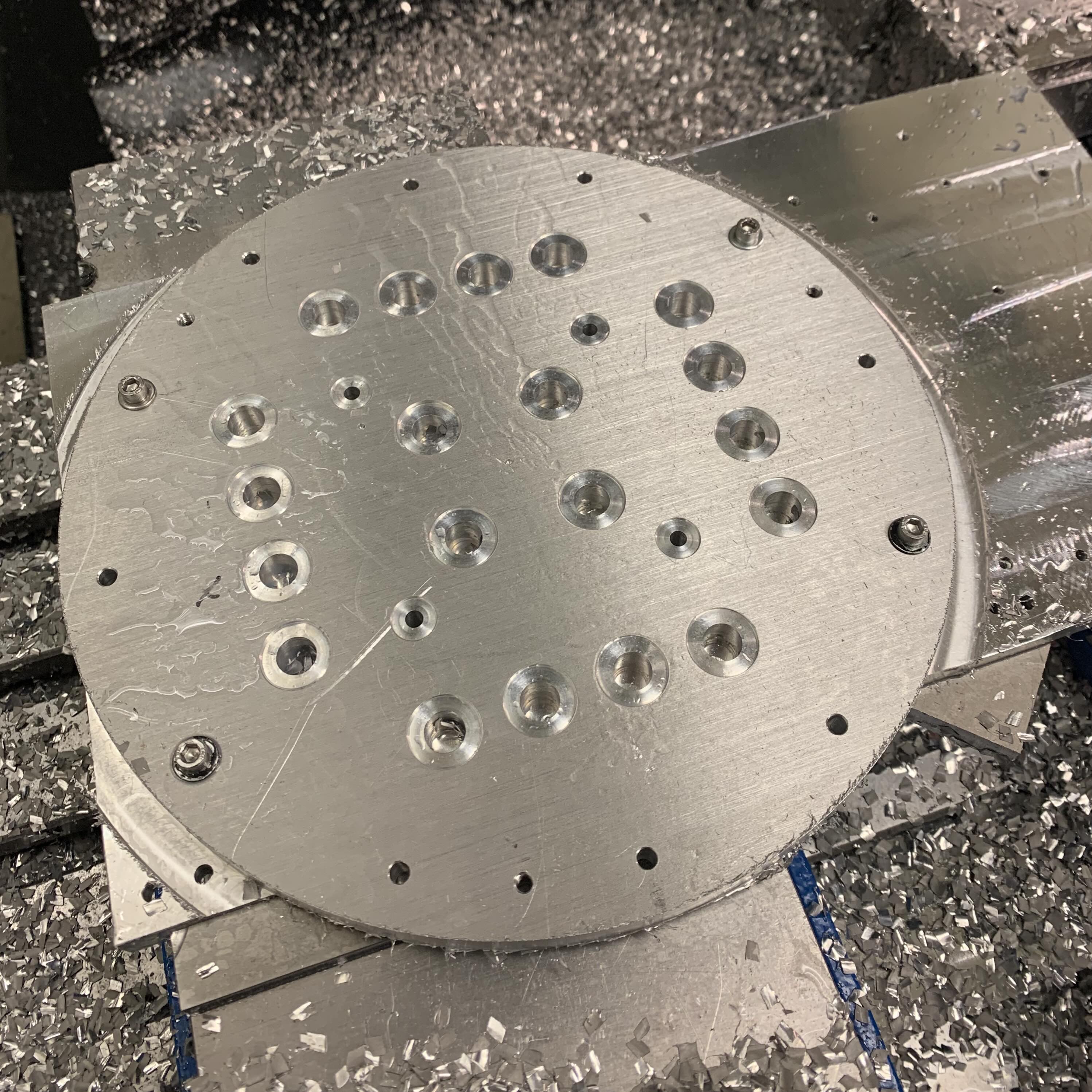

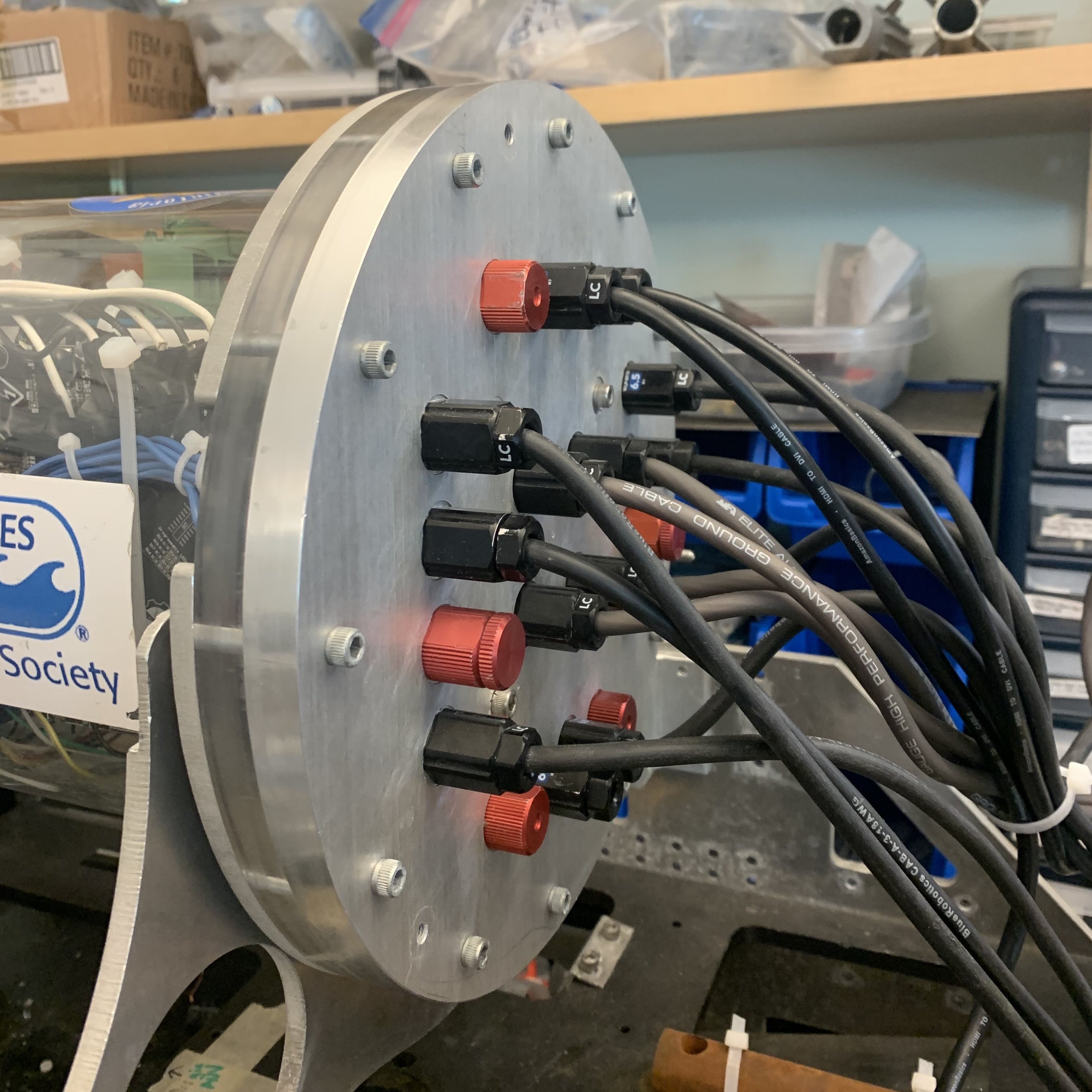

AUV Endcap

This endcap was milled for the Autonomous Underwater Vehicle Interdisciplinary Club (AUVIC). 20 holes were spot-faced and drilled into a large aluminum plate for WetLink penetrators, with 4 additional holes for the internal mounting system to be attached.

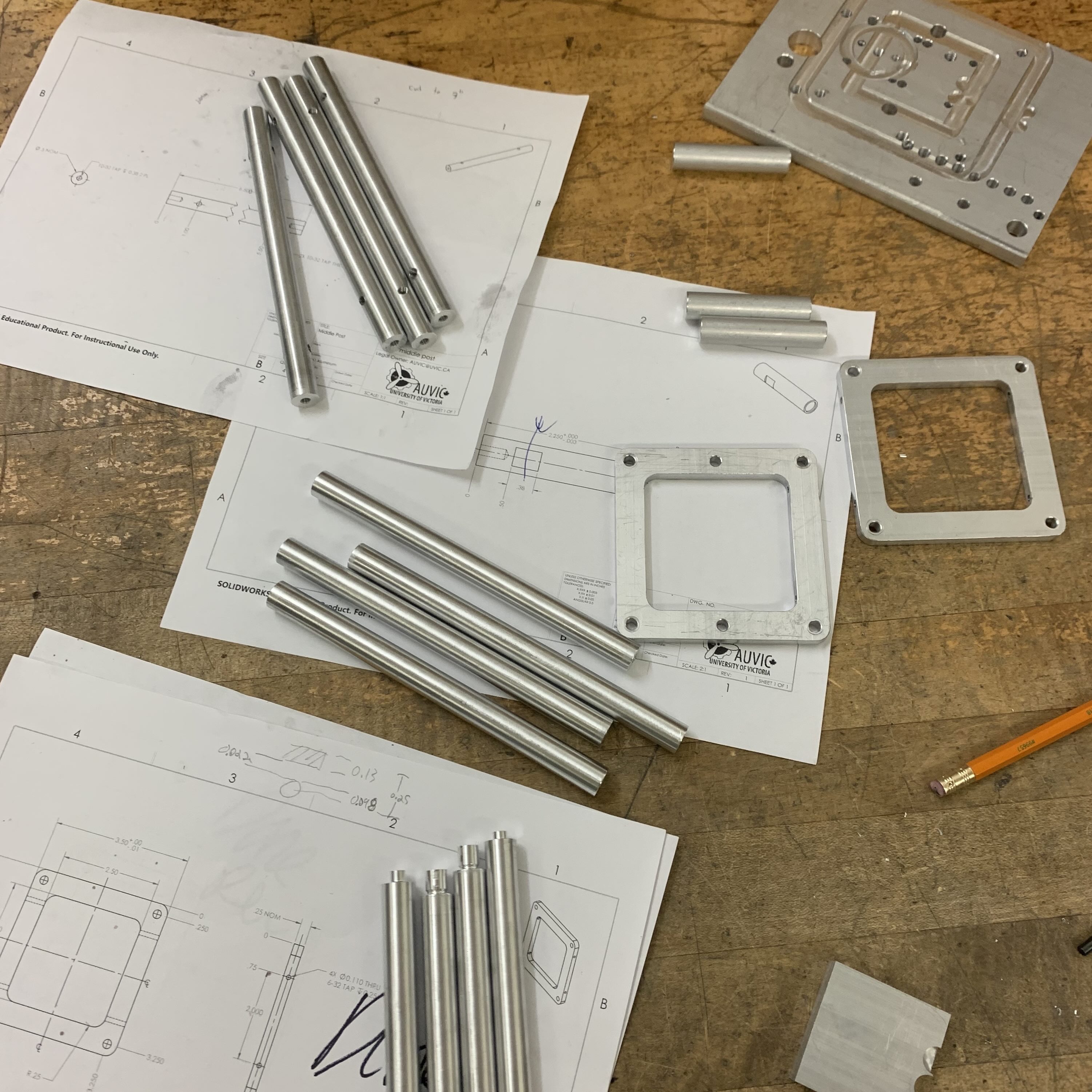

AUV Internal Components

Post and plate parts were turned and milled from aluminum to hold the electronics and payloads inside of an AUV and a rocket for UVic student design teams.